Description

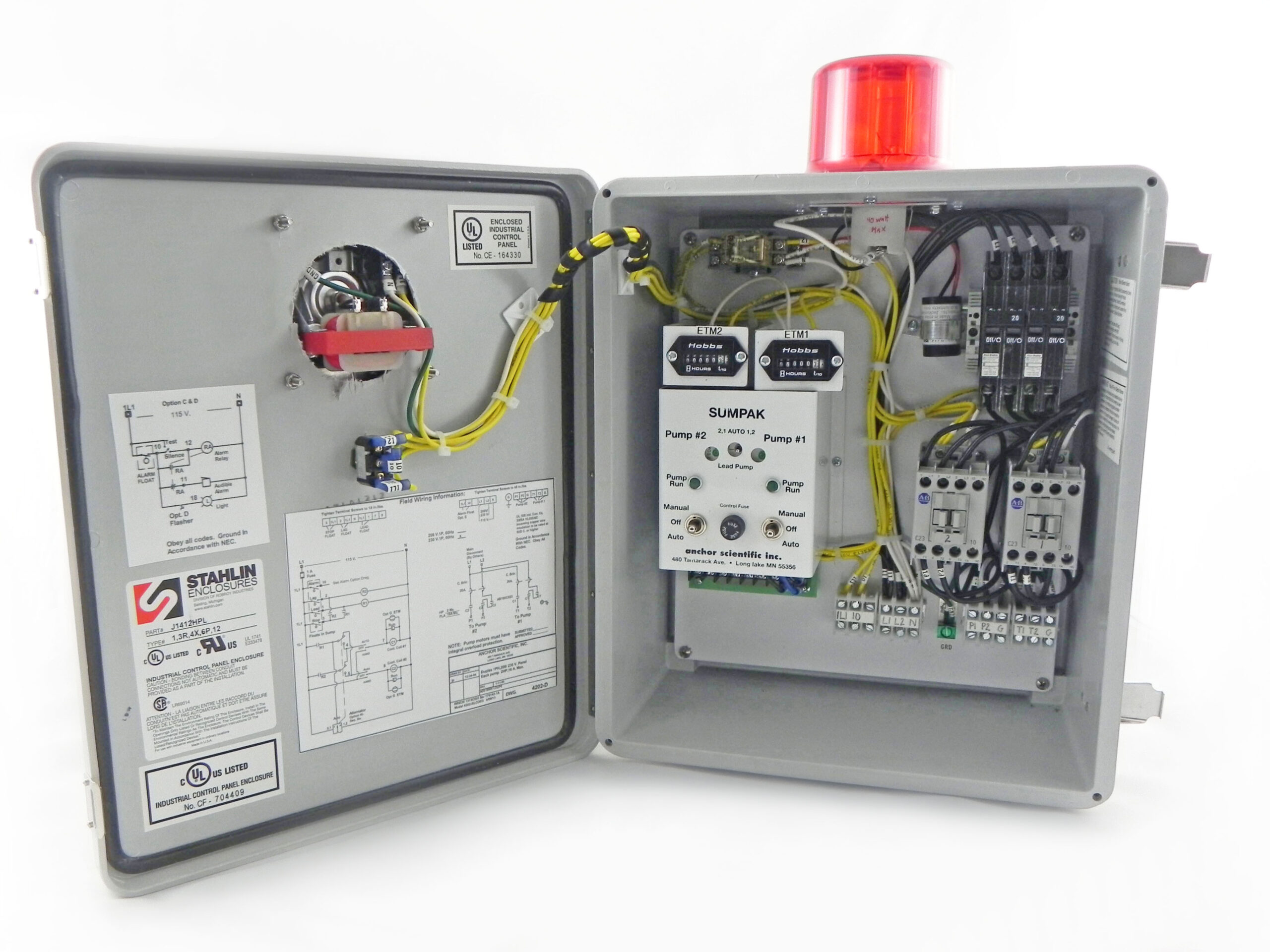

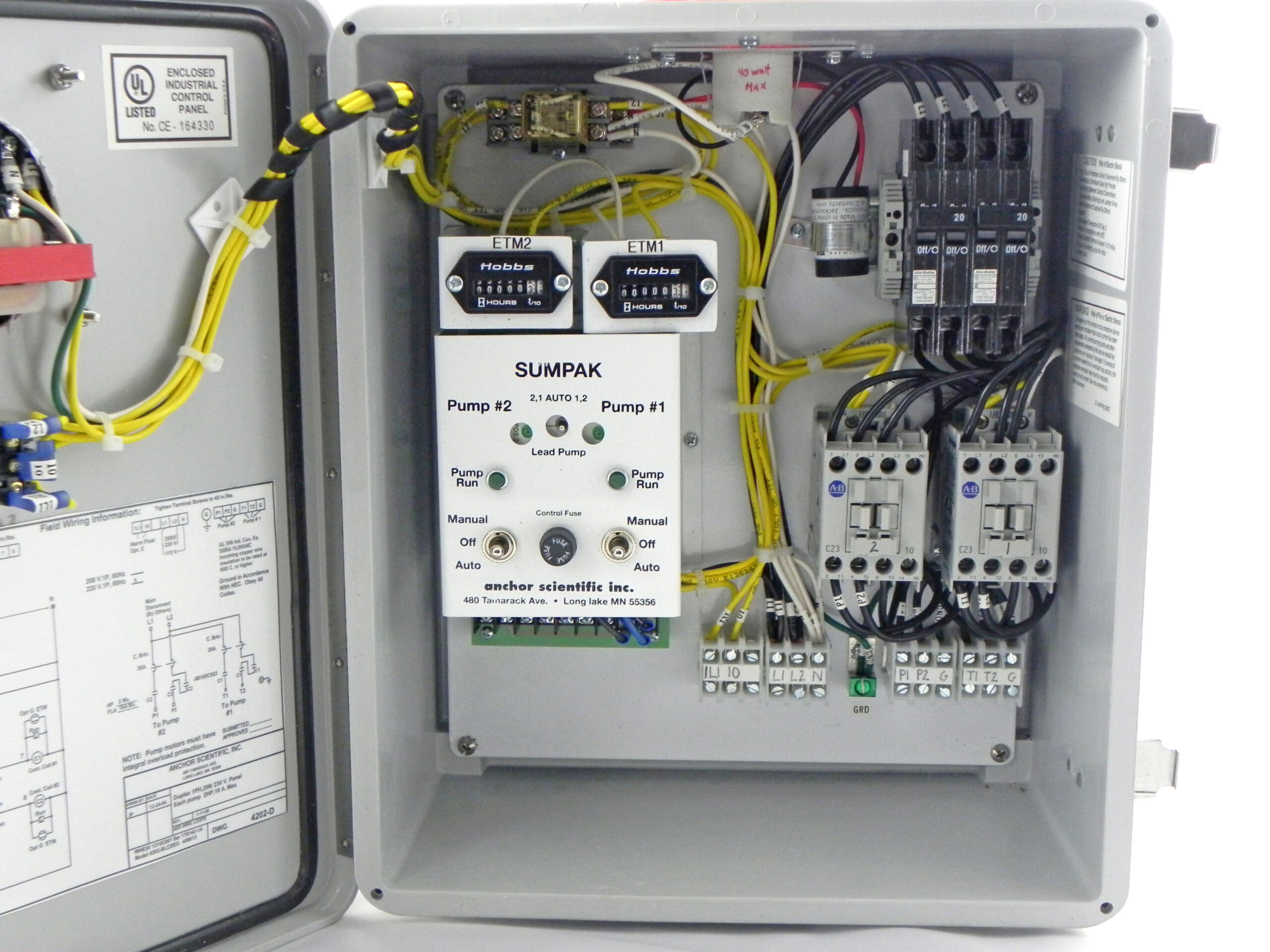

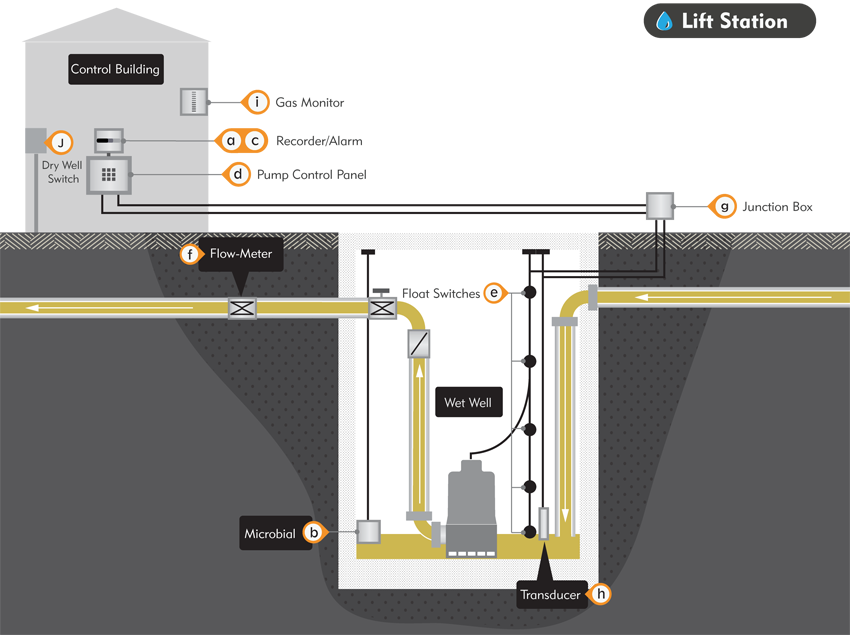

The Series 4200 Duplex control panel is offered with the sumpak controller in a standard configuration control panel to provide dependable, automatic operation of single phase pumps. The controller will automatically alternate the lead-lag pump sequence in a two pump system. Upon completion of a pumping cycle, the alternator unit reverses the sequence of operation of each pump, the lead pump of the just competed cycle now becomes the lag pump, while the lag pump becomes the lead pump for the next cycle. This type of setup has many advantages, including equalized wear on the two pumps, increased reliability of the lag pump and standby capacity for peak inflows or lead pump failure. Typically three float or diaphragm switches are wired to the terminal strip. One switch is a “lead float” switch, another a “lag float” switch, and the third a “stop float” switch. The switches control two pilot duty relays through a holding circuit arrangement, which eliminates the problems associated with short cycling and alternator “chatter” due to contact bounce. When the alarm option is added, the “lag float” also becomes the alarm contact. The alarm is held in until the pumping cycle is completed and the liquid level reaches the “stop float”. At this point the alarm will reset automatically. It is also possible to use a fourth switch for the alarm. This float can be set at a higher or lower level than the “lag float”. A higher setting may serve to eliminate some of the nuisance alarms caused by peak flow conditions.